Funded Research Projects

I-Corps: Translation Potential of an Advanced Air Filtration System that Captures Particulate Matter and Carbon Dioxide

- Funded by National Science Foundation

- Directorate for Technology, Innovation, and Partnerships, 2025-2026

Fundamental Study of the Dynamic and Thermal Behaviors of Supercooled Droplet Interacting with Plasma Discharge

- Funded by the Department of Energy (DOE) Office of Science (SC)

- Research in Basic Plasma Science and Engineering, 2023-2026

GOALI/Collaborative Research: Nonlinear Energy Dynamics of Aerodynamically Coupled Oscillators

- Funded by National Science Foundation

- NSF Grant Opportunities for Academic Liaison with Industry (GOALI), 2022-2025

- Funded by National Science Foundation

- NSF Engineering Research Initiation (ERI), 2022-2025

A Fundamental Study of the Anti-Icing Mechanisms of a Bacteria-Spores-based coating in Mitigating Dynamic Droplet Impinging and Freezing

- Funded by CCNY TREAD.

- The CCNY Converge to Translate (C2T) Program, 2025-2028

Development of a Bio-Inspired Bacteria-Spores-based Anti-/De-Icing Surface

- Funded by CUNY ASRC Seed Grant

- The Advanced Science Research Center (ASRC) Collaborative Seed Grant Program, 2024-2026

Development of a High-Energy Laser-based Thermal-Flow Diagnostic System

- Funded by GRTI Round 24

- City College of New York GRTI Award, 2024-2025

Investigation of Supercooled Droplet Impinging and Freezing Dynamics on a Novel Durable Slippery Surface

- Funded by The Professional Staff Congress-City University of New York (PSC-CUNY) Research Award Program

- PSC-CUNY Enhanced Award, 2023-2024

Investigation of Droplet-Plasma Interactions

- Funded by The City College Initiative to Promote Academic Success in STEM (CiPASS)

- CUNY CiPASS Grant, 2023-2024

NIH-STTR: Non-Invasive Physiologic Evaluation of Peripheral Arterial Disease

- Funded by National Institute of Health (NIH) STTR award via Rfpi, Inc

- NIH STTR Grant, 2019-2021

Development of an Advanced Spray Diagnostics Test Rig for the Characterization of Biofuel Spray Flows Exhausted from Liquid Fuel Injectors

- Funded by Natural Resources and the Environment Research Cluster (NRE) of East Carolina University

- ECU NRE Seed Grant, 2020-2021

Our Research Facilities

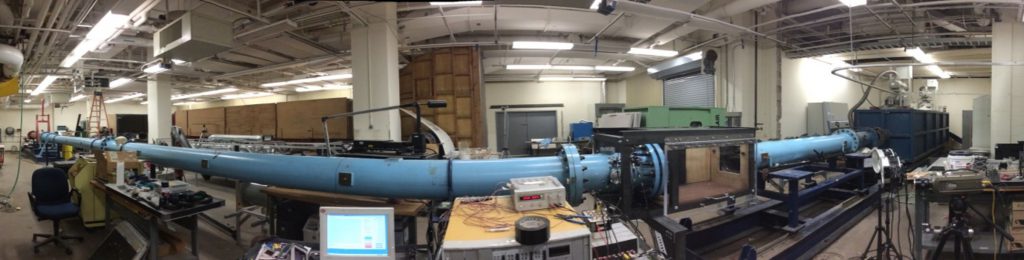

CCNY Shock Tube/Tunnel Research Facility

This large-scale facility is a high-resolution aero-thermodynamic facility that belongs to the Department of Mechanical Engineering at CCNY.

The facility has several distinguishable features that make it particularly suitable for fundamental and applied research in high-speed flows. The most significant of them is the ability to control the flow velocity and improve the flow quality behind the shock wave after its reflection off the end wall, by changing the porosity of the end wall. In a closed-end shock tube, the reflected shock interacts with the viscous boundary layer, and it bifurcates to form the so-called Mark’s bubble, which can result in a massive separation of the flow and therefore can significantly deteriorate the flow quality. The porous end wall, which is used in the present facility allows for the mass flow to exit the working section and establishes a non-stagnant flow behind the reflected shock.

The second major characteristic of this facility is its large size, 12″ in diameter and 88 ft long, which provides an unprecedented platform for high spatial resolution measurements of turbulence in ranges that have never been investigated before. Measurements of turbulence scales of the size of the Kolmogorov viscous length scale have already been obtained in this facility and the dynamics of compressible turbulence are being investigated.

The facility is also equipped with a nozzle to generate flows at Mach 6 and operate in a shock-tunnel mode. Shock waves with Mach number 3 can be achieved in the regular shock tube transient facility mode.

CCNY Large-Scale Environmental Wind Tunnel Facility

The CCNY Large-Scale Environmental Wind Tunnel is an open-ended suction type, with 1.2 m x 1.2 m cross-section and has 8.4 m long working area. It is powered by a 20hp, 460V, 3 phase frequency controlled AC motor, driving axial fan with 7 blades rotating at a maximum rpm of 1750 delivering 32000 cubic ft/min. capacity providing a maximum speed of 15 m/s in the working section. Varying frequency from 0 to 100 % in 5% increments can control the flow velocity. The motor and fan assembly, which is housed in a sound-absorbing diffuser allows low noise operation of the facility and low levels of acoustical noise transmitted in the working section. It is also mounted on a frame, which rests on eight springs to minimize vibration, and isolates the motor and fan assembly from the working section. Three sides, top, bottom, and one wall of the working section are of one-inch plywood while the other wall has four Plexiglas windows also of 1-inch thickness for optical access and observation.

Our Research Interests

1. Shock/Blast Physics and Shock/Blast Mitigation Technologies

Flow-Surface Interactions in Compressible Turbulent Flow

•Effects of surface textures on the boundary layer flow structures (In Progress)

•Role of temporal variation of sub-structures on turbulence modification

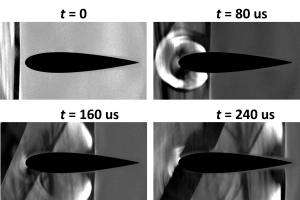

High-Speed Multiphase Interactions Driven By Shock/Blast

•Shock-droplets interactions (In Progress)

•Shock-plasma interactions

•Shock-dust/particle interactions

Development of Shock/Blast Mitigation Technologies

•Programmable and scalable soft surfaces (In Progress)

•Effects of droplet cloud parameters on shock/blast mitigation (In Progress)

•Droplet-surface interactions driven by shock/blast flows

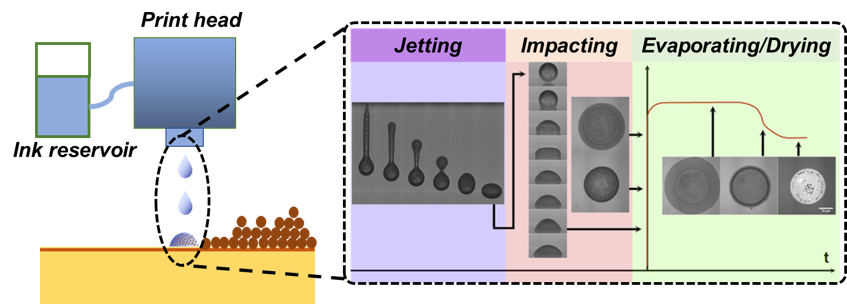

2. Multiphase Flow and Heat Transfer in Additive Manufacturing

Multiphase Interactions in Binder-Jetting 3D Printing

•Dynamics of Binder drops impacting on a powder surface (In Progress)

•Effects of binder properties on the imbibition dynamics in printing

•Effects of powder density and size on the binder drop dynamics

Development of a Freezing-Based Inkjet 3D Printing Technique

•Dynamic and Thermal behaviors of colloidal drops in freezing process (In Progress)

•Multi-droplet interactions in freezing-based inkjet 3D printing

•Development of more efficient sublimation techniques

Thermal-Flow Behaviors of Colloidal Drops under Microgravity

•Development of a ground-based microgravity test rig for 3D printing

•Impact dynamics of colloidal drops in microgravity conditions

•Freezing/sublimation thermodynamics of colloidal drops under microgravity

3. Multiphase Interactions in Energy Systems and Devices

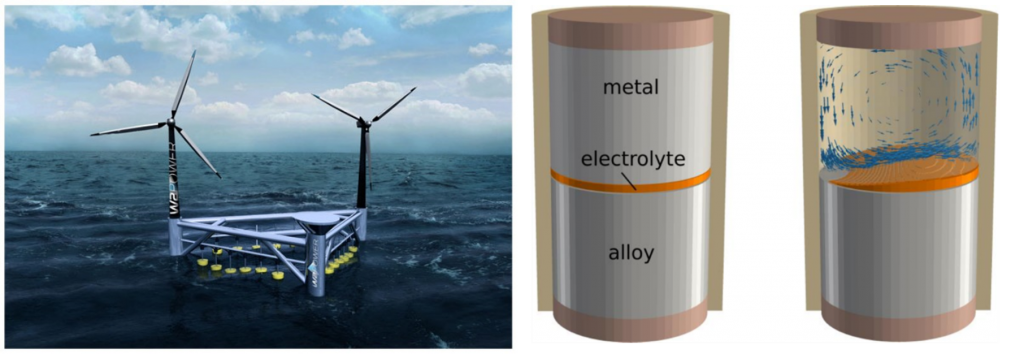

Thermal Flow Diagnostics of Liquid-based Energy Storage Device

•Ultrasound-based velocimetry and thermometry techniques

•Multiphase interactions during charging-discharging cycles

Multiphase Flow and Heat Transfer in Oil-Gas Production and Processing

•Interfacial dynamics in multiphase energy systems

•Phase-change thermodynamics in fluid energy systems

•Droplet formation and dynamics in multiphase energy systems

Offshore Wind/Wave Energy Systems and Devices

•Unsteady flow dynamics of offshore wind turbines and wind farms, and wave-energy-converter (WECs) (In Progress)

•WInd/Wave energy analysis in offshore atmospheric boundary layer conditions